High-impedance grounded neutral systems are permitted to serve 277-volt loads – High-impedance grounded neutral systems have gained prominence in electrical distribution, offering unique advantages in serving 277-volt loads. This article delves into the technicalities, code requirements, design considerations, and maintenance aspects of these systems, providing a comprehensive understanding for engineers and practitioners.

The implementation of high-impedance grounding in 277-volt systems enhances safety, reduces fault currents, and improves system stability. However, it also introduces specific design challenges and maintenance considerations that require careful attention.

Introduction

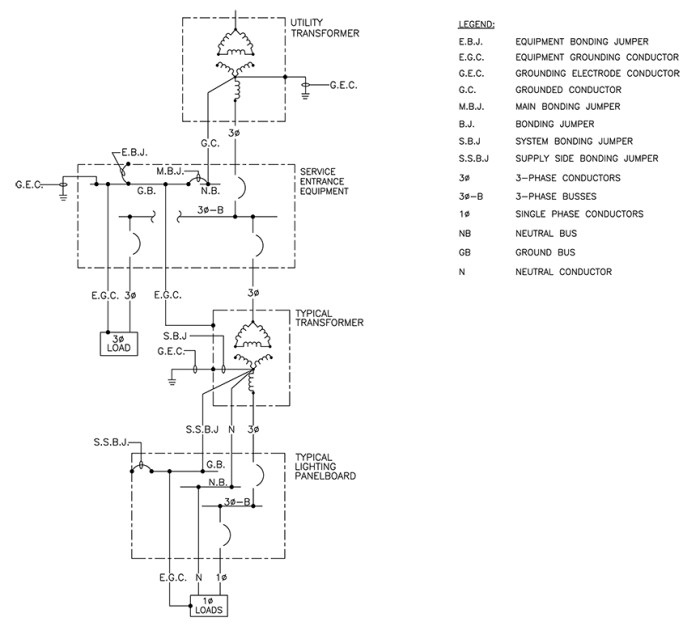

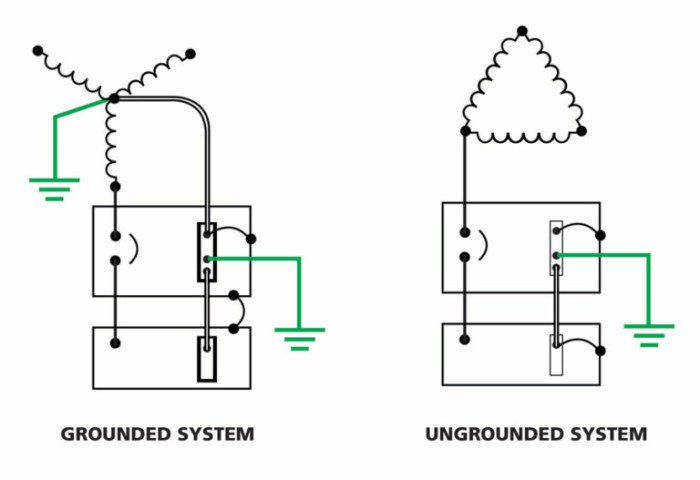

High-impedance grounded neutral (HIGN) systems are electrical systems in which the neutral point of the transformer is connected to ground through a resistor or impedance. The purpose of grounding in electrical systems is to provide a low-resistance path for fault currents to flow, thereby protecting equipment and personnel from electrical shock.

HIGN systems offer several advantages over solidly grounded systems, including reduced fault currents, improved arc-flash protection, and reduced voltage distortion. However, HIGN systems also have some disadvantages, such as the potential for nuisance tripping and the need for special equipment.

Code Requirements: High-impedance Grounded Neutral Systems Are Permitted To Serve 277-volt Loads

The National Electrical Code (NEC) requires that HIGN systems be used in certain applications, such as healthcare facilities, data centers, and industrial plants. The NEC also specifies the minimum impedance that must be used for HIGN systems, as well as the maximum voltage that can be used on HIGN systems.

When serving 277-volt loads, the NEC requires that the impedance of the grounding resistor be at least 5 ohms. This is to ensure that the fault current is limited to a safe level.

HIGN systems are commonly used in applications where it is important to minimize the risk of electrical shock, such as healthcare facilities and data centers.

Design Considerations

When designing HIGN systems, it is important to consider the following factors:

- The size of the grounding resistor

- The type of grounding electrode

- The overcurrent protection devices

The size of the grounding resistor is important because it determines the amount of fault current that will flow in the system. The type of grounding electrode is also important because it determines the resistance to ground.

The overcurrent protection devices must be selected to protect the system from damage in the event of a fault.

Maintenance and Troubleshooting

Regular maintenance is important for HIGN systems to ensure that they are operating properly. Maintenance tasks include:

- Inspecting the grounding resistor

- Testing the grounding electrode

- Checking the overcurrent protection devices

Common problems that can occur with HIGN systems include:

- Nuisance tripping

- Ground faults

- Overvoltage

If you experience any problems with your HIGN system, it is important to contact a qualified electrician to troubleshoot the problem.

Case Studies

There are many successful implementations of HIGN systems in a variety of applications. One example is the use of HIGN systems in healthcare facilities. HIGN systems are used in healthcare facilities to reduce the risk of electrical shock to patients and staff.

Another example of the use of HIGN systems is in data centers. HIGN systems are used in data centers to reduce the risk of damage to electronic equipment.

HIGN systems can be a valuable tool for reducing the risk of electrical shock and damage to equipment. However, it is important to design, install, and maintain HIGN systems properly to ensure that they are operating safely and effectively.

FAQ Corner

What is the primary advantage of high-impedance grounding in 277-volt systems?

High-impedance grounding limits fault currents, reducing the risk of equipment damage and electrical hazards.

What are the key design considerations for high-impedance grounded neutral systems?

Proper grounding electrode design, selection of appropriate overcurrent protection devices, and consideration of system harmonics are crucial design factors.

What is the importance of regular maintenance for high-impedance grounded neutral systems?

Regular maintenance ensures the integrity of grounding connections, prevents corrosion, and identifies potential issues before they become faults.